Soft-Bodied Robotics @ Nemitz Robotics Group

GOALS: Design a pneumatically actuated hand out of ultra-soft TPU

SKILLS: CAD, Arduino, Iterative Design, 3D Printing

This is a project I worked on during Spring 2025 where I designed this pneumatically controlled hand out of 3D printed raw TPU pellets as a demonstration of the applications of a novel 3D printer for ultra-soft materials. This demonstration is currently a part of a research paper under review for publication!

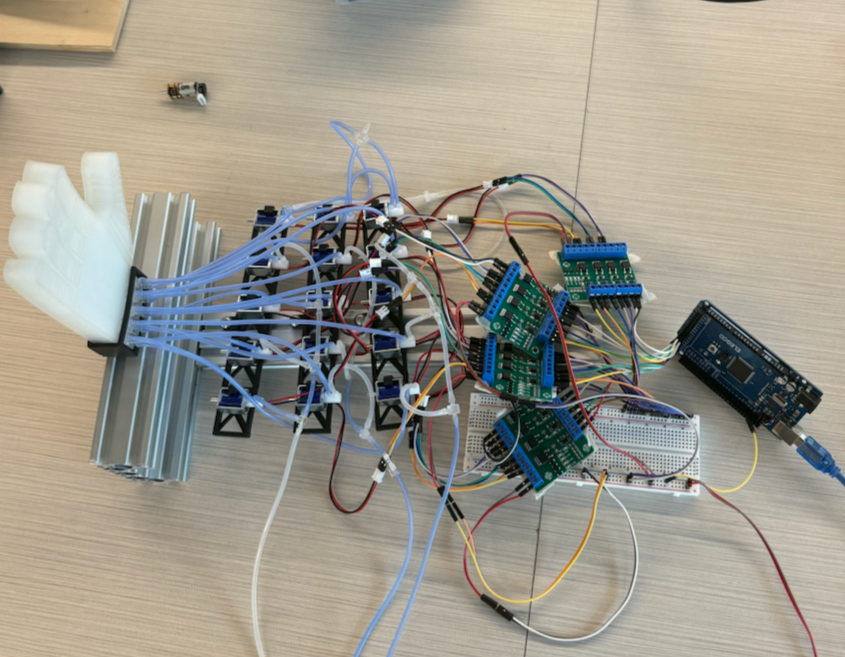

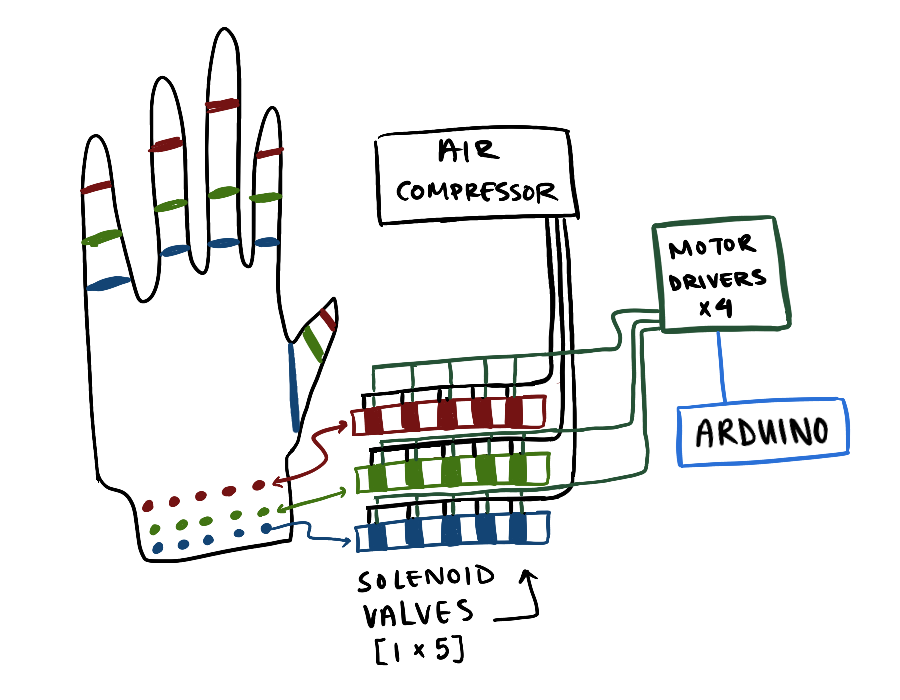

Electronics

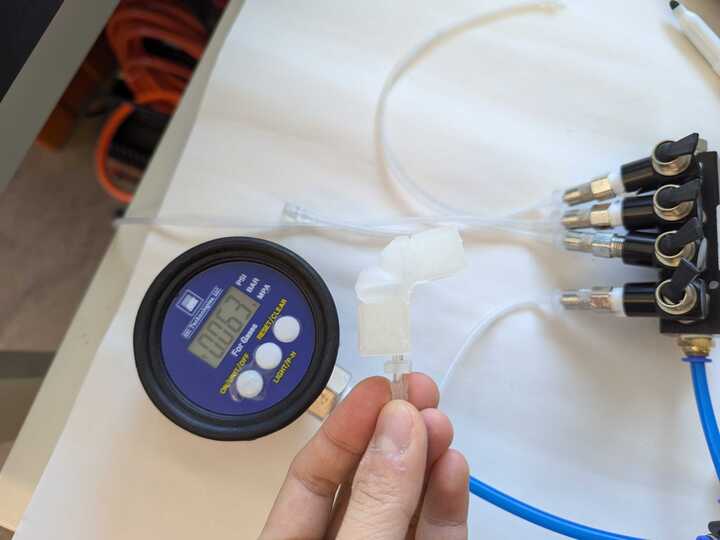

This electromechanical system was a monster to set up. I really wanted each joint to be individually controllable, which ment wiring up 15 solenoid valves both the the microcontroller and the air compressor - one for each of the 3 joints on each of the fingers.

This electromechanical system was a monster to set up. I really wanted each joint to be individually controllable, which ment wiring up 15 solenoid valves both the the microcontroller and the air compressor - one for each of the 3 joints on each of the fingers.

CAD

This is the CAD Model for what the internal channels of the

hand looks like.

Code

The code is just a pretty simple script to turn certain solenoid pins

on and off. Here's an example that curls each finger individually!

Model Progression

3D Sculpting

After completing the simple hand model, I wanted to figure out a way to make the hand look more realisitc. I used a program called NomadSculpt to digitally sculpt a realistic hand model, and used the CAD model for all the internal channels to boolean those shapes out. This gave me a way to blend organic shapes and structured channels, which was super cool :-)